Sealmac Styles

Sealmac seals are constructed using heavy-duty fabricated metal cases. All spring-loaded sealing lip designs utilize metal end plates, offering additional strength and stability.

Spring-loaded designs may be manufactured to withstand pressures up to 10 bar (150psi). Special designs are available to 25 bar (375spi).

Sizes

Within manufacturing limitations, any size seal, inch or hard metric, is available thus eliminating the need to consult a manufacturer’s catalogue for tooled sizes.

There is no charge for tooling, minimum production quantities or for special tolerances.

Extended life for a damaged housing bore or shaft is possible by machining to correct the problem then selecting a Sealmac seal to meet the new dimensional requirements.

Standard, Semi-Dual, and Dual style Sealmac Seals are avai lable in any Outside Diameter (OD) from 2.500 inches to 48.000 inches (65mm through 1220mm). Seal Inside Diameter (ID) and width for a given OD IS subject to a minimum producible section. The chart below lists the minimum seal section for each range of seal OD’s. These values calculate a seals maximum ID and minimum width.

Springless and high-pressure seal designs have different minimum sections. Leather seals may have smaller ID. Information on seal ID and width limitations is available on request.

Materials

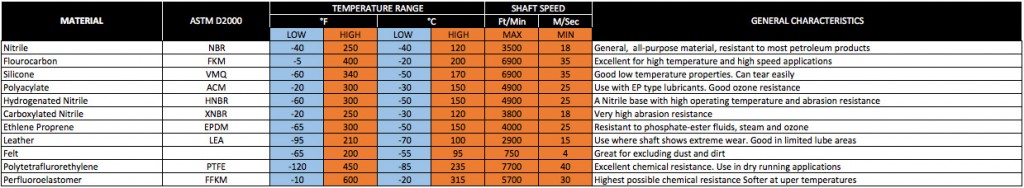

The correct selection of elastomeric and metal case materials is critical for optimal seal performance in any application.

All materials have characteristics and properties that predict their response in specific environments.

The most commonly used materials are listed below.

Detailed information on these and other, more specialized, materials is available on request.

Lips

Sealmac’s manufacturing method allows selection of the most application appropriate lip material for any style.

Sealmac’s metal case materials are also available in any seal size. Mild Carbon Steel is a general-purpose material, SAE 1006-1008, cold rolled. It is treated for protection during handling. Stainless Steel is available when corrosion resistance is required. SAE 304 or SAE 316 may be selected. Brass and Aluminium cases are available for applications requiring non-ferris materials .

Springs

Sealmac springs are sized for optimal performance based on diameter and application material requirements.